The power module is one of the key components of an Electric Vehicle. A power Module is a combination of Semiconductor Technology and packaging technology. Semiconductor manufacturers are also started to enter into Power Module Business due to the high demand for the component.

The Power Module market is defined into 3 major categories – Moulded Halfbridge Power Module, 6P, and Discrete Power Module. 6P architecture is in demand due to its benefits. Nowadays a customers are(OEMs, Tier I) expecting One Power Module device which suits their 400V and 800V vehicle architecture with the same size and dimensions.

Currently, 3 major key markets are looking fit for Power Module China, Europe, and the USA. The market size of Power Module will touch $16.2B by 2030 with a CAGR of between 14 to 16% from 2023 to 2030. The growth of the Power Module Business depends on several market Dynamic factors like the Type of Power Module, and the Electric Vehicle Market growth. The availability of semiconductors is also going to play a role. Other factors which affect the market’s size and growth are the semiconductor’s price trend, Yield loss, Electric Vehicle Type, New Technology development, and Acceptance of discrete devices. In our report, we have examined each point in detail and its impact.

We Analysed the Power Module packaging material Technology Trends, Innovation, and Price fluctuation like Baseplate, Semiconductor chip, Copper, Silver, Substrate, Mould Material, Wire Bonding machine, Test machine, and Logistic cost.

Tier 1 Suppliers, OEMs, and Power Module are looking to control the manufacturing cost. Another key challenge is the forecast methodology of the Power Module included every cost component for the next 10 years.

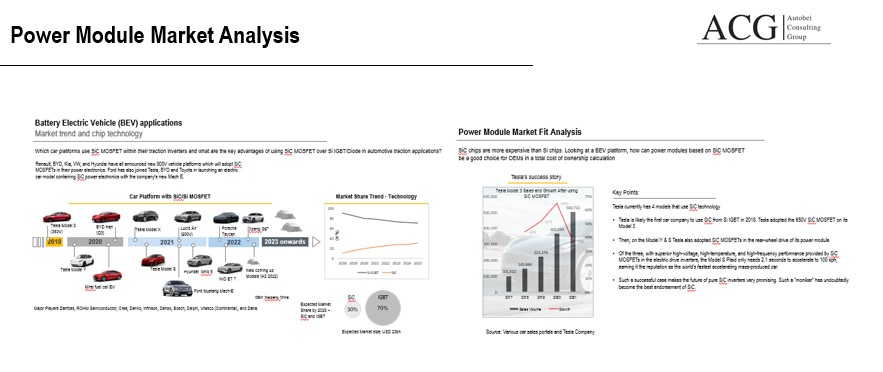

The key selling factors of the Power Module are High Energy Density, Size, Weight, Ease of installation, Thermal loss, peak temperature performance, Cost Vs Benefits, and maturity of the Technology for Silicon carbide. However, there is a high-cost difference noted between Si and SiC technology. Both technology IGBT and MOSFET are suitable for different EV applications. Europe is leading in Si and SiC, the USA is sourcing the Power Module mainly from Tier I, and China is still struggling to source IGBT locally.

The electric vehicle Industry is expecting the top-side contacts to reduce thermal losses. New technology excludes the substrate material, replacing the aluminum lead frame. This change saves power Module costs.

For vehicles like SUVs, Trucks need highly reliable and robust power Modules. Some metals like copper and silver sintering have a heavy cost impact on Power Modules.

Process development is another challenge mainly for Power Module manufacturers, but other stakeholders are suffering due to process development.

Some Power Modules are with minor customization but are expensive. However, most of the Power Modules are following the Infineon Power Module design and pattern.

Key highlights of the report:

- The market size of Power Module in terms of Value and Units – Trend and Forecast

- Market Share Analysis of Power Module

- Region-wise ( USA, China, Europe, and RoW) market size and Potential

- Key Challenges and Key Growth Drivers

- Power Module Competitor Analysis – Infineon, Hitachi, STMicro, Vitesco, ONSemi, Rohm, Bosch, StarPower, Mitsubishi, and others Cooling Technology Comparison

- Number of Semiconductor chips per Module

- Business Model Analysis – Semiconductor Chips, Power Module, or Inverter

- Technology Challenges and Opportunities

- Product – Market Fit Analysis

- Risk Analysis